Glass-making is a complex process,

inquiring about our products isn’t!

Harnessing the splendour of glass

Innovation, infrastructure and ingenuity of shaping glass into spectacular glass packaging

The genesis of our immaculate glass flaconnage happens in the minds of our experts. Even before the innovation, technological advancements and automated processes, we believe that glass-making is an art, and its soul lies in the creativity of our artisans. Our expertise lies in our deep understanding of this artform, and the best-in-class infrastructure we have built over the years to facilitate its expression. We believe that our infrastructure and quality standards are at the foundation of our storied rise.

Our dedicated and modern infrastructure led by experts manages complex profiles, thick bottom, off-centric neck, and tall bottles. Our premium perfume line is designed with straight-conveyors to handle such complex bottle shapes and the furnace is built using European refractory for all glass contact areas, the entire batch-path is lined with stainless steel, thus preserving glass clarity and avoiding contamination. The manufacturing lines have a four side fire-polishing facility for a finer surface finish and capability to develop stainless steel mould for superior skin finish. We also have a dedicated furnace to produce feeder colour bottles. We are using a magnetic separation system and 100 percent snow-white Quartz to provide better glass clarity. We have implemented a vertical load test targeting 100 kg as per market requirement with a minimum of 70 kg in general. At the cold-end area, we have online automatic inspection systems from Visiglas (France) in a closed, air-conditioned, dust and contamination free environment. The fact that every third nail polish bottle in the world is manufactured by us, speaks volumes about now just our capabilities, but also the trust the industry has in us.

The global pharmaceuticals industry standards are becoming more stringent, with more focus on greater operational effectiveness to tackle the tough market scenario. We, at PGP, are dedicated to meet these standards, and develop ourselves as a reliable partner for the industry. We have a modern, ISO 15378 certified facility for type-1 glass packaging with global regulatory and process compliance. Our type-1 glass vials and infusion bottles are suitable for complex pharma products like liquid injectable drugs, oncology and lyophilized products because of their excellent hydrolytic resistance and a lower coefficient of thermal expansion. Our manufacturing plant is also ESP (European Pharmacopoeia) compliant. We have a professional team, fully trained according to the GMP norms to ensure the highest maintainable quality. In tandem with the global pharma industry norms, we also ensure the safety of both our teams and products that we supply through multiple processes and rigorous checks.

Our facilities

We have three facilities: two in India, Kosamba and Jambusar, and one in Sri Lanka, Horana, with an overall capacity of 1,600 tonnes per day, 11 furnaces and 64 production lines.

Each facility offers its own speciality within our product range, along with in-house decoration services, making us uniquely positioned to cater to different clients with personalised services.

Kosamba, India

Jambuasar, India

In this facility, we have one of the world’s largest single installed capacities for pharmaceutical packaging in amber-glass. We produce pharma-grade type III amber-glass bottles and vials, along with type III flint bottles for the pharmaceuticals, C&P, and Specialty Food & Beverage industries.

Horana, Sri Lanka

Outside India, we produce type III flint and amber glass bottles for the Pharmaceutical, Cosmetics & Perfumery, and Specialty Food & Beverage industry in our Horana, Sri Lanka facility. Here we also have infrastructure in place to produce Feeder-Coloured bottles in various shades and a dedicated in-house glass bottle printing facility.

Fired by Imagination

Design

Before any of the heavy machineries are turned on, our creative minds get to work. They ideate, innovate and collaborate to come up with designs that exceed client expectations, every time. From complex, nuanced layouts to simpler designs, our team of experts excel at turning your vision into spectacular glass bottles.

Innovation

We believe that if you don’t evolve, you’ll be left behind. In an industry that is constantly changing, our focus is always on improving our skill sets and expertise with New Product Development. We challenge ourselves every step of the way, be it the shape, complexity, sustainability or efficiency, we are on a constant path of improvement.

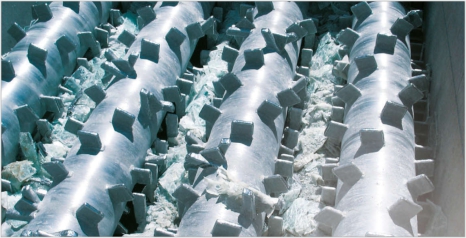

Mould

At PGP, every step of the process of producing the best-in-class glass flaconnage is handled by a team of experts and high precision machinery. Moulding is no different. The entire process is fully automated, and only the best machines are used at the facilities, ensuring every glass bottle meets our, and industry’s very high standards for quality.

6 CNC Vertical Machining Centre,

4 CNC Turning Machines,

1 CNC 3D Engraving Machine,

28 Conventional Machines,

Two CAM Workstations (Using UNIGRAPHICS NX 5),

for generating optimum & precise tool path,

Mould Polishing Machine,

CNC Gun Drilling Machine,

Spark Vent Hole Drilling Machine

Technology in use

6 CNC Vertical Machining Centre

4 CNC Turning Machines

1 CNC 3D Engraving Machine

28 Conventional Machines

Two CAM Workstations (Using UNIGRAPHICS NX 5)

for generating optimum & precise tool path

Mould Polishing Machine

CNC Gun Drilling Machine

Spark Vent Hole Drilling Machine

Moulded to Perfection

Making a glass bottle is science, but creating a glass bottle that is excellent in quality, and magnificent to look at, is the culmination of science and art at its finest. The process of turning grit into PGP’s pristine glass packaging takes imagination, precision, and a lot of dedication. From our laboratories that test the raw materials, furnaces to hot- and cold-end facilities, we have invested in the best machinery and talent to ensure what we produce isn’t just irreplaceable, but also irreplicable.

Raw materials

Without quality raw materials, there is no high-quality glass packaging. Our well-equipped laboratories and batch house ensures every ounce of raw material we use is of excellent quality.

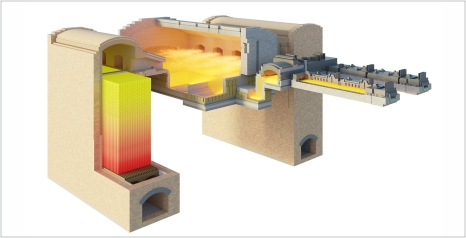

Glass manufacturing

This is where our passion for glass meets best-in-class technology across our facilities. We use furnaces from Horn and Sorg, Germany, glass forming machines from Emhart, Switzerland and Bottero, Italy, among others.

Cold-end

After all the collaboration, designing, and high-temperature processes, this is where we handle our creations with utmost care. Our annealing lehrs are from Pennekamp, Germany & India and our ware handling machines are from Sheppe, UK.

Quality & inspection

Quality assurance and quality control are our prime strengths, made possible by diligent processes and best-in-class inspection machines. Each bottle has to pass through multiple quality checks before it’s shipped.

Our Infrastructure - Machinery & Equipment

Batch House

Zippe - Germany

Cullet Scraper

Zippe - Germany

Furnace

Horn - Germany; Sorg - Germany

Forehearth

Sorg - Germany; Horn - Germany; BH-F - UK

Glass Forming Machine

Bottero - Italy; Emhart - Switzerland; Sanjin Emhart; BDF - Italy;

Annealing Lehr

Antonini - Italy; Vulcan-Bowman - U.S.A

Bottle Stacker

Sheppee - UK

Inspection Machines

Iris - France; Heye - Germany; Tiama - France; Visiglass

Lab Equipment

AGR - Thermal Shock/Pressure, Annealing Polarimeter, Bottle Dimension Inspection

Compresson

Atlas Copco - Sweden; Ingersoll Rand - USA

Mold Making CNC Machine

Haas - Germany; Mazak - Japan; Röders, - Germany

All images are copyright to their respective owners/manufacturers

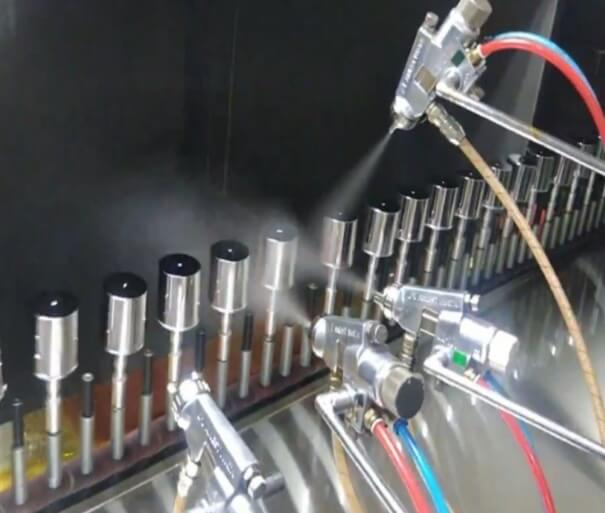

Decoration

We offer specialised inhouse decoration services with a wide range of finishes in perfume, personal care, and speciality liquor & food segments. Our decoration facilities located in Kosamba (India) and Horana (Sri Lanka) are led by experts thriving on challenges and constantly offering innovative solutions, from conception to final commercial development.

Printing

Technology in use

Ceramic, Organic & UV printing

Screen Printing & pad printing

Machines

Fully Automatic 2/3 Colour Kammann, Germany

Dubuit automatic (3 station & 6 Station, France)

Ardenghi, Italy

Semi Automatic (Techno, Hankey & Dubuit)

Coating

Technology in use

Partial Coating, Masking & Coating, Matt Coating, Gloss Coating

Machines

Four fully automatic coating M/C indigenous

Metallising

Machines

A fully automatic metallising machine from Taiwan

Hot foil stamping

Machines

Hot Foil Stamping machines with silver, copper & gold foiling facility

Automatic Printing Machines Kammann

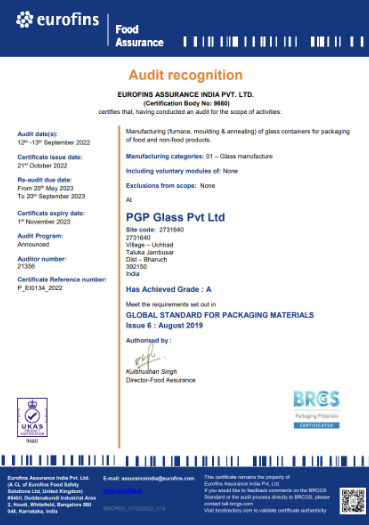

Our Quality Certifications

The quality of each of our products is the crown jewel of PGP’s legacy. We undertake comprehensive checks and audits, at the incoming, in-process and final stages of manufacturing using automatic and best-in-class inspection equipment. Our five-level quality inspection process ensures every glass bottle bears the hallmark of our trust and adheres to internationally recognised quality standards.

15378 Certificate

BRC Certificate 2022 EI0134 2022

BRC Packaging Certificate E02718 2020 1

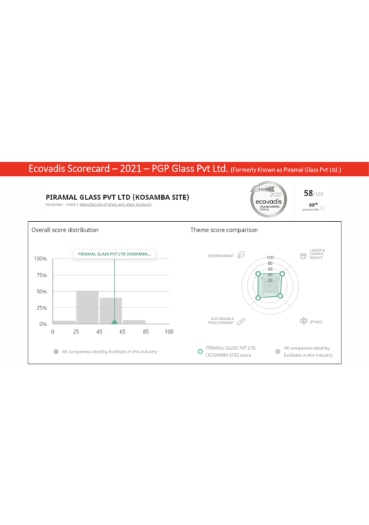

Ecovadis Scorecard 2021 1

Ecovadis Scorecard 2021 2

FSSC Certificate PGP Private limited

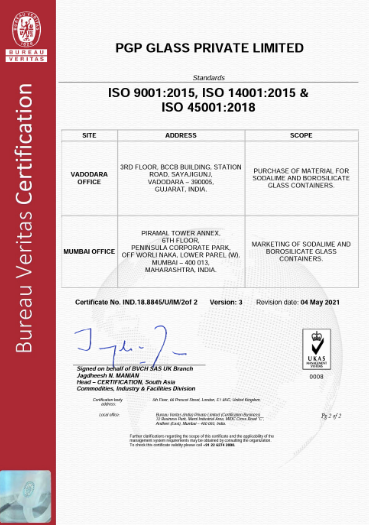

IMS Cert. PGP GLASS PRIVATE LIMITED V3 01 1

IMS Cert. PGP GLASS PRIVATE LIMITED V3 01 2

IMS Certificate - KSB -07.01.2022 1

IMS Certificate - KSB -07.01.2022 2

ISO 15378 Certificate PGP Glass

ISO 15378-06.04.2023

ISO 90012015 Certicate

ISO15378 Certificate PGP glass private limited

SA 8000-2014 Certificate 21.11.22